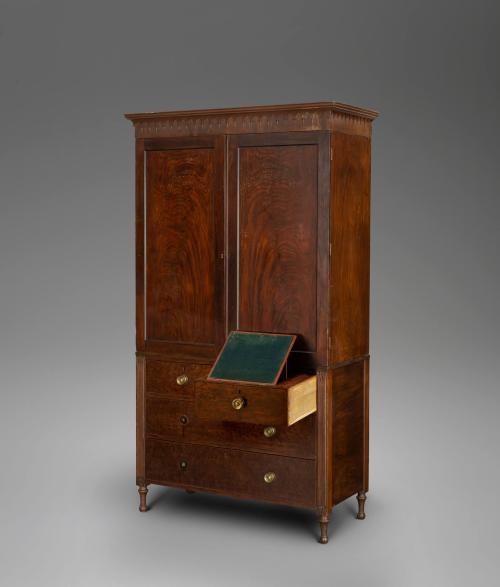

Clothespress

DateCa. 1810

MediumMahogany, mahogany veneer, yellow pine and poplar.

DimensionsOH: 78"; OW: 48"; OD: 22 3/8"

Credit LineMuseum Purchase

Object number1996-67

DescriptionAppearance: Two part clothespress; upper case consists of a gothic arched cornice molding above two paneled doors; interior of upper case contains four sliding clothing trays with scrolled sides; lower case consists of a reeded waist molding, two small drawers over two full length each drawers each with one or two round brass pulls and inset brass keyhole escutcheons, and turned feet; drawers flanked by applied reeded pilasters terminating in leaves at the top and a half rosette at the base; proper left small drawer fitted with a hinged baize covered writing surface with a angled support that slides back when drawer open to reveal interior, and a pencil section with a sliding lid.Construction:

On the upper case, the vertically grained mahogany sides are half-blind dovetailed into the top and bottom, both of which are yellow pine An interior medial shelf of yellow pine with mahogany facing on the front edge is joined to the sides with sliding half-dovetails.

Mahogany slide supports are screwed to the interior of the sides with early screws.

On the panel back of the upper case, the rails are tenoned into the side stiles and a medial stile is tenoned into the rails. The two single board tulip poplar panels are chamfered on the backside to fit into dados in the yellow pine frames. The back is screwed into rabbets in back edges of the sides with early screws and nailed with rose-head nails into the back edge of the top and bottom.

The rails of the panel doors are tenoned into the stiles. The matchbook panels are slightly chamfered on the back to fit in dados in the stiles and rails. The doors are hung with box hinges. An applied vertical molding on the edge of the proper left door covers the gap between doors when closed.

Two battens are nailed to the underside of the bottom of the upper case to hold it in place.

The front and back rails of the removable cornice are dovetailed to the side rails and the joints are reinforced with vertical glue blocks in each corner. A vertical medial rail is half-dovetailed to the front and back rails. The cornice is held in place with rectangular blocks glued to the case top in each corner that butt join the front and back rails and corner blocks of the cornice frame when it is in the proper position. Four additional rectangular blocks are glued to the front and back rails of the cornice frame (back rail blocks are missing) and are drilled with screw holes that match ones in the top of the case; the medial rail is fitted for a pocket screw with matching hole in the top. All of these screws are missing. The cornice is of tulip poplar, with mahogany veneer on exposed front and sides.

The one-piece mitered mahogany molding on the front and sides of the cornice is glued to triangular full length blocks that are in turn glued and possibly nailed to the front and side cornice rails. The bottom edge of the molding is shaped with integral gothic arches over applied turned drops.

On the lower case, the yellow pine top is dovetailed into the tops of the front and back mahogany stiles and into a series of vertically grained, butt joined tulip poplar blocks that are in turn glued to the sides between the stiles. Nailed to the upper surface of the top is a yellow pine frame with miter joined tulip poplar front and side rails; back rail is butt joined to side rails. A 1” x ¾” beaded mahogany mitered belt molding is glued to the front and side outer edges of the frame. The assembled frame is nailed from above to the outer edges on the top and a single nail in each front stile. The molding over-laps the stiles by 1/16”. Integral beading on the front stiles terminates at the top with carved leaves; a fan of leaves is carved underneath the beading

The single board horizontally grained mahogany sides are tenoned into the stiles. The yellow pine bottom is double-tenoned into the stiles and nailed from below into the edge of the back and into front-to-back 1 ½” x 3” tulip poplar blocks that are in turn glued to the sides and also serve as drawer guides for the bottom drawer.

The back is comprised of two butt-joined horizontal yellow pine boards, tenoned into the rear stiles, extending flush with the back edge of the top and bottom. It is nailed from above to the top and to the bottom from the underside.

Drawer blades are double-tenoned into the front stiles. The drawer divider is double-tenoned into the top and through double-tenoned to the upper drawer blade. Blades and divider are of tulip popular faced with mahogany. A medial rail is tenoned into the back and joined to the upper drawer blade with a single large dovetail. It provides interior drawer support for the two upper drawers; the interor drawer guide is nailed to the upper surface of the medial rail. The outer drawer guides are 1½” x 2¼” tulip poplar boards butt joined to the front and back stiles and glued to the sides. Drawer supports are nailed to the drawer guides. Two thin drawer stops are glued to the upper surface of the drawer blades and case bottom under each drawer

Turned feet are tenoned into the stiles.

The tulip poplar sides of the drawers and trays are dove-tailed to the mahogany fronts and tulip poplar backs. On the large drawers and trays, a medial front to back rail is tenoned into the fronts and nailed from below to the bottom edge of the back. Tulip poplar bottoms are chamfered on the underside to fit into dados in the front sides and medial rails and are nailed from below to the back. Five closely spaced blocks are glued to the bottoms and sides underneath the dados on all drawers but not on the trays. The smaller drawers are of the same constructions as the large but without the medial rail.

The dividing panel in the secretary drawer is set in grooves in the drawer front and back creating a 2” wide side compartment. The bottom of the compartment is set in grooves in the dividing panel and side as are the dividers within the compartment. The writing surface and compartment top slide in grooves in wooden strips that have been nailed to the top edge of the shortened sides. The rails of the frame in which the writing surface rests are through tenoned to each other, rabbeted on the inside to receive the writing surface, and notched within the rabbets to allow variation of angle of the easel . The top rail of the writing surface frame is tenoned into its side rails. The writing surface is tongue and groove joined to the side rails and covered with baize. The two arms of the easel are hinged to two blocks which are in turn screwed to the back of the writing surface; the arms are through tenoned to the crossbar which provides for variation of the writing angle.

ProvenanceHistory provided by vendor was that the clothespress was bought in northeastern North Carolina from family descended part from northeastern North Carolina and the other from Norfolk.

1800-1815

ca. 1775

1805-1815

ca. 1820

ca. 1830

1750-1775

1760-1780

1815-1820

1760-1780

ca. 1740

1810-1820

1790-1810