Tall Case Clock

Date1805-1815

Retailed by

William McCabe

MediumMahogany, white pine, glass, iron, brass, and steel

DimensionsOH: 100 1/8" OW: 19 3/4" OD: 9 1/2"

Credit LineMuseum Purchase

Object number1930-174,A&B

DescriptionAppearance: HOOD: molded arched top surmounted by three fluted plinths with brass ball and spire finials; pierced fretwork between plinths; glazed arched hood door flanked by fluted columns with brass capitals and bases; arched top rectangular glazed side lights on hood; white painted arched dial signed below arched date aperture "William McCabe/ RICHMOND.", Arabic hour and minute numerals, seconds dial with Arabic numerals above hour and minute hands, revolving painted moon dial, fronted by hemispheres, gilded raised scrolls in corners of dial; eight day weight driven movement with anchor-recoil escapement. TRUNK: wide cove molding below hood; fluted quarter columns on trunk with brass capitals and bases; rectangular trunk door with molded edges and applied molding forming a rectangle within the door; coved waist molding above base with applied molding forming a square within base; scalloped skirt and French feet.Construction: On the hood, brass finials are screwed into fluted plinths nailed and probably tenoned into the cornice. The hood top boards are nailed in place, set onto the top of the tympanum at the front and onto an arched rear rail open dovetailed into a spacer block that is behind the cornice molding and has thin mahogany veneers on the exposed bottom. All of the large moldings on the clock are applied white pine cores that are triangular in cross section. The outer hood door frame has mitered corners and flat brass hinges that rotate on screws set into the case itself. The inner hood door frame is nailed to the inside of the tympanum and is locked in position by the glazed side panels nailed to the back of the cornice molding and through-tenoned into the hood runners. Plain flankers are flush-nailed into the rear of the side panels and set in a small dado at the top. The hood columns are set into brass bases and capitals nailed to the case. The lower hood molding is flush-nailed to the runners.

On the trunk and base, a full-height back board is widened at the top and bottom with flankers, and the entire assembly is nailed into rabbets on the rear of the case. The seat board rests on rails that abut the tops of the case sides and are flush-nailed into dadoes on the back board. These rails also sit in small rabbets cut into plinth blocks that top the quarter-columns. The shoulder molding is glued and nailed to the case. Quarter-columns with brass terminals sit between wooden plinths and are butt-joined to the sides and front of the trunk. The mortised-and-tenoned door frame consists of a two-piece upper rail on which the white pine top extends above the shoulder molding on the inside of the case. The corresponding door frame stiles consist of quarter-inch-thick-facades backed by white pine cores that extend inside the case the full depth of the column and are glued to corresponding kerfed white pine blocks that cover the reverse side of either column, extend to the case sides, and terminate at the top above the top rail. The door has a veneered facade set onto a white pine board with battens at the top and bottom. The waist molding is glued and nailed to the lower part of the trunk and sits on the top edges of the base panels. These panels are further secured with small interior glue blocks. The butt-joined side and front panels of the base are backed with small interior glue blocks and faced with mahogany veneers. The front panel is further adorned with a thin astragal- molded frame. The foot and skirt assembly are replaced.

The clock features an eight-day, weight-driven tall case movement with an anchor-recoil escapement regulated by a seconds-beating pendulum. A rack-and-snail striking system sounds the hours on a bell. The twelve-inch arched dial is of painted iron. There are blued-steel hour, minute, and seconds hands, a date aperture below the dial center, and a lunar indication in the arch.

The plates are cast brass with all surfaces hammered, filed, scraped, and stoned. Four smaller-than-normal cast and turned brass pillars are riveted to the backplate and pinned at the front plate. The seat board is attached with steel screws threaded into the bottom pillars. The brass tube barrels are grooved and have applied end plates pinned in place. Tailed steel clicks are threaded into the great wheels, and plain brass click springs are riveted in place. The closed-end brass collets are pinned into the great wheels. The cast-brass wheels are of normal thickness with a combination of standard and longer than standard epicycloidal teeth and have four-arm crossings. The center and third wheels are mounted on pinions; the rest are secured on plain stepped brass collets. There are cut pinions and tapered arbors. The pallets are mounted on a stepped collet. The back-cock has two steady pins. The pendulum has an brass rod and a four-and-one-half-inch brass-faced lead bob. The striking system has a center-mounted hammer, the hammer spring is screwed to the backplate, and the hammer counter is screwed to the pillar. The four-inch bell is bell-metal. Its standard is screwed to the outside of the backplate. The conventional motion work is uncrossed, and the minute wheel and its brass pinion run on a start screwed into the front plate. The end of the bridge is a modified square that is slightly convex rather than perfectly straight. There is a twelve-hour date work. A twelve-hour lunar work appears in the arch. Four cast and turned brass dial feet are secured directly to the front plate. There are normal brass pulleys with steel stirrups. The fourteen-and-one-half-pound, filled tin-plate weights are painted black. Each has a wire eye for hanging.

Materials: Mahogany fretwork, plinths, moldings, hood flankers, hood side panels, hood door frames, columns, trunk sides, trunk door veneer, and base veneers; white pine top boards, arched rear rail on hood, molding cores, door core, base panel cores, back board, seat board, seat board supports and corresponding stiles, upper trunk rail, and interior glue blocks; iron, brass, and steel movement.

Label TextThe emergence of large-scale manufacturing and increased labor specialization after 1800 caused clockmaking in America to change considerably. Leading the way was the Willard family of Massachusetts, who, beginning in the 1790s, established clock production on an unparalleled scale. Theirs was among the first modern technological industries in the country. Although four Willard brothers were involved in the clock trade, Simon (1753-1848) and Aaron (1757-1844) were primarily responsible for merging the basic principles of design, construction, inventory, and distribution to achieve large-scale production. Key to their success was the Willards' pioneering use of premanufactured parts, some produced by specialized artisans in America's emerging factories and others imported from British manufacturers. In the end, the Willards created the first American clock manufactory capable of serving a national market.

CWF owns several timepieces by the Willards, including a tall clock with a movement by Aaron (accession 1930-52). The distinctive form of the tall cases used by the Willards is now commonly referred to as the Roxbury style in recognition of the town just outside Boston where many of the clocks were made. However, the case design--minus the bracket feet, fretwork gallery, and fluted quarter-columns--was originally based on British clocks in the early eighteenth-century Palladian taste. Simon and Aaron Willard, who worked both together and separately, hired local cabinetmakers to produce Roxbury cases. Because the craftsmen followed uniform methods of production, it is now difficult to distinguish the work of specific individuals. Perhaps inspired by the Willards' success, at least seven other coastal Massachusetts clockmakers used virtually identical cases, some by the same cabinetmakers who worked for the Willards. As clockmakers trained by the Willards established shops elsewhere in New England, the case design was gradually dispersed. Although the Roxbury case evolved over time to reflect changing fashion, many elements remained constant, most obvious among them the template-cut fretwork atop the arched hood.

The clock shown here is obviously akin to Roxbury examples, but because the dial is marked "William McCabe / RICHMOND," both movement and case were long thought to be Virginia productions modeled on New England timepieces. It is now clear that movement and case alike were made in Roxbury or Boston for export to the southern market. In fact, the case is structurally and stylistically identical to documented Roxbury examples. Made of mahogany and white pine, it displays the fretted top ornament characteristic of New England clocks, while the hood, shoulder, and waist moldings closely match those on eastern Massachusetts cases. In typical Roxbury fashion, the quarter-columns stand on rather tall plinths but there are no corresponding blocks above the capitals. The closely spaced white pine glue blocks that reinforce the joints between the columns and the case sides, and the horizontally laminated rail above the door (mahogany on the bottom and white pine above), also mimic New England construction. The case even features nailed-on rails to support the movement and seat board. This detail, common in the Boston area, is almost never seen in the South where seat boards usually rest directly on the upper ends of the case sides.

The movement to which McCabe added his name also copies the Roxbury-Boston variety, and the white dial closely resembles the imported British dials on many Willard clocks. Horologist David Todd believes, however, that a modest percentage of the white dials in America, including some used by the Willards, were American made. The absence of a false plate on the McCabe movement strongly suggests that the dial is American, as does the slightly inferior nature of the brass casting. The hands closely resemble those on other Willard clocks but are unlike common British examples and probably were made by a Roxbury or Boston artisan as well.

Records confirm that McCabe was a trained clockmaker. As early as 1804, McCabe placed notices in the Richmond newspapers expressing gratitude to residents for their past patronage and noting that he continued to make and repair "all kinds of Watches and Clocks." McCabe continued to produce and retail a wide range of timepieces during the next decade, moving his shop several times and regularly taking on new apprentices and journeymen. McCabe also served as a captain in the local militia, which explains why he sold military articles like epaulets, plumes, and cockades.

After 1810, McCabe regularly announced the availability of "Watches and Clocks of every description," including gold and silver watches, eight-day clocks, and watch keys and seals. Although McCabe continued to make some movements, as demonstrated by his purchase in 1813 of a "Cutting Engine" at the estate sale of another Richmond clockmaker, he also advertised imported English and French timepieces at the "SIGN of the Large GOLD WATCH." In an effort to expand his business, McCabe also sold clocks at Robert Poore's furniture wareroom, one of the many new local retail outlets where both locally made and imported furniture was available. McCabe was still at work as late as 1820.

That McCabe added his name to a movement imported from New England was neither unusual nor intended to deceive his customers; instead, it was an advertisement. Putting his name where the owner of the clock could see it frequently was logical because repairs and annual cleaning and oiling were important parts of every clockmaker's business. Charleston, South Carolina, clockmaker Joshua Lockwood followed the same practice fifty years earlier by importing British tall clocks and engraving his name on the brass dials.

McCabe's long, prosperous career in Richmond is representative of the experience of other early nineteenth-century urban clockmakers. Once expensive objects reserved for the wealthy, clocks and watches became increasingly available after 1800, largely due to the emergence of manufactories like the Willards', Seth Thomas's, and Eli Terry's, and retail shops like McCabe's. This development coincided with a changing awareness of time that is reflected by the creation of the timed workday and the installation of large clocks in church towers and government buildings. The success of the Willards, McCabe, and countless other post-Revolutionary artisans was tied to the profound way in which time and timepieces became essential parts of the daily routine for Americans at almost all levels.

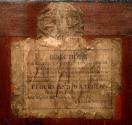

InscribedThe dial is marked in black ink or paint "William McCabe / Richmond." A paper label mounted inside the trunk door consists of a watch paper with the image of a crowned figure within a columned recess surmounted by the phrase "cemented with love." Adjacent to this is an oval panel with the words "Wm. McCabe / Clock & Watch Maker / Richmond / Warranted to perform." Printed around the edges of the watch paper are the words "The silent breast and secret heart Preserves the mystery of the art."17 Mounted below the watch paper is a decoratively bordered set of instructions that read "DIRECTIONS / FOR SETTING UP AND REGULATING CLOCKS. / First plumb the Clock case and make it fast to the place / it is to stand at; hang on the weights and give motion to the / Pendulum.--To make the Clock go fast, screw the nut up / which is under the Pendulum--and to go slow, let the nut down. / CLOCKS AND WATCHES / OF EVERY DESCRIPTION, / Sold, Repaired and Warranted, by / WILLIAM M'CABE."

"F. M. Shirey, January 1951, for Colonial Williamsburg, Va.," a modern cleaner's inscription, is engraved on the front plate of the movement.

MarkingsNone

ProvenanceCWF purchased the clock in 1930 from Bessie Brockwell, a Petersburg, Va., antiques dealer who specialized in early southern decorative arts.

ca. 1775 (movement); 1805-1815 (case)

1805-1815

1795-1805

1790-1800

1800-1815

1814-1825

1815-1820

1765-1785

1765-1785

1760-1780

1770-1780

ca. 1810