Tall Case Clock, movement

Date1810-1813

Maker

Seth Thomas

Maker

Silas Hoadley

MediumOak, cherry, laurel, white pine, tulip poplar, iron/steel, and lead

DimensionsOH: 16 1/4"; OW: 11 7/8"; OD: 5 1/2"

Credit LineGift of Juli Grainger

Object number2008.2000.2,B

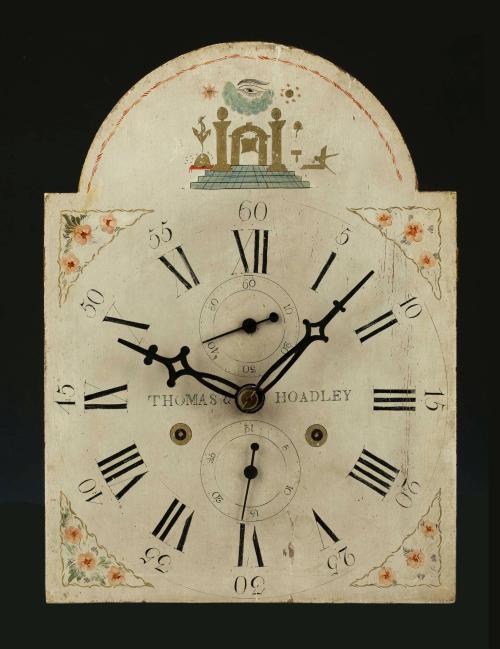

DescriptionDial:One piece arched painted 11 7/8”W x 16”H wood dial signed THOMAS & HOADLEY between the IX and III. Roman numeral hour dial with Arabic minute labels in 5 minute intervals on outer band. Arabic seconds dial in 10 second increments immediately below 12. Arabic calendar with date markings and labeled at 5-10-15-20-25-31. Clock dial arch painted with Masonic imagery including an eye, sun and moon, two columns flanking an arch at the top of four steps with a Bible (?) in the center of the arch, a beehive, compass, square, anchor, mallet, and trowel. Painted floral spandrels in dial corners. Gold trimmed false time and strike winding arbors. “5th” and “56” marked on back of dial.

Movement description:

Eight day wood time, strike, and calendar weight-driven movement measuring 8 11/16” H x 6 1/8” W. Plate thickness is 0.262”. Clearance between front and back plates is 2.75”. Clock has an anchor-recoil escapement regulated by a seconds beat pendulum. A count wheel strike sounds the hours on a 3.7” diameter cast bell. The count wheel is mounted to the back of the back plate.

With the exception of the escape wheel, all time and strike train wheels are solid wood. The escape wheel is brass on a wooden arbor. The conventional wood motion work is solid. The pendulum crutch is an open loop.

Instead of the usual 4 pillars commonly found to fasten the front and back plates, three wooden pillars are riveted into the top of the front plate and pinned at the back plate. The center pillar is slotted vertically and serves as the pendulum spring mounting. The bottom of the front plate is fastened to the seat board via a mortise and tenon joint. The back plate extends beyond the seat board and is fastened via two wooden pillars that protrude from the back of the seat board. This design eliminates the need for two of the longer pillars and combines movement plate securing with seat board mounting, thereby eliminating the two hooked rods and corresponding nuts that are common on brass tall case clock movements to secure the movement to the seat board.

Each main wheel drum has two cords wrapped around it. The clock is wound by pulling down on one cord which turns the main wheel core which in turn pulls the weight bearing cord up and wraps it around the core, thus winding the clock. This design eliminates the need for metal winding arbors, a clock key, holes in the dial, and weight pulleys.

Woods: white pine seat board, tulip poplar face; oak plates; cherry and fruit wood wheels, feet, and arbors.

Label TextEarly-19th century furniture made from inexpensive, plain wood was often faux grained to mimic more valuable, visually exciting wood. Wooden rather than metal mechanisms helped make tall clocks more affordable to middle class customers, including the unknown owner who personalized his dial with a Masonic emblem.

Inscribed"5th" and "56" inscribed in ink/black paint on back of face.

Markings"THOMAS & HOADLEY" painted on dial.

ProvenanceDonor purchased from Frank & Barbara Pollack in 2001. Said to have been found in a home in Westbrook, Maine.

Exhibition(s)

1809-1813

1819-1829

1809-1814 (movement); ca. 1825 (case)

1808-1820

ca. 1760

ca. 1810

ca. 1760

ca. 1720

ca. 1810

1793-1796

1805-1815

1765-1785