Tall case clock Works

Date1765-1785

Artist/Maker

Thomas Walker

MediumBrass, steel, iron, and bell metal

Credit LineGift of Mrs. C. T. Lanham.

Object number1984-271,B

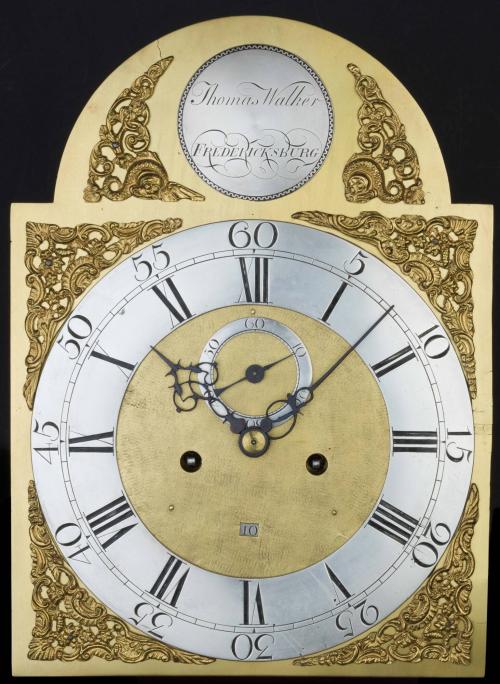

DescriptionThe clock features an eight-day weight-driven tall case movement with an anchor-recoil escapement regulated by a seconds-beating pendulum. A rack-and-snail striking system sounds the hours on a bell. The twelve-inch-wide cast-brass arched dial has cast-brass corner spandrels. The dial plate was cast with voids behind the chapter ring and roundel to save on metal. There are blued-steel hour, minute, and seconds hands. A date aperture appears below the dial center. The plates are cast brass with all surfaces hammered, filed, scraped, and stoned. Four cast and turned brass pillars are riveted to the backplate and pinned at the front plate. The movement was originally secured with seat board screws threaded into the bottom pillars but now is attached with hooks over the bottom pillars. The brass tube barrels are grooved and have applied end plates pinned in place. Tailless steel clicks are threaded into the great wheels; plain brass click springs are riveted in place. The closed-end brass great wheel collets are pinned in place. The cast-brass wheels are of normal thickness with longer than standard epicycloidal teeth. The center and third wheels are mounted on pinions; the rest are on plain step-collets. There are cut pinions and parallel arbors. The pallets are mounted on a step-collet. The square steel crutch-rod has a closed-end fork and is riveted into the pallet arbor. The back-cock has two steel steady-pins. The pendulum has a steel rod and a three-and-one-half-inch diameter brass-faced lead bob. The striking system's center-mounted hammer has a hammer spring on the backplate with an L-shaped stop threaded into the upper pillar to act as an adjustable counter. The standard of the four-inch diameter bell-metal bell is screwed to the inside of the backplate. There is a conventional motion work. The cannon and minute wheels have three-arm crossings, and the brass minute pinion runs on a start screwed into the front plate. The bridge is round-ended. There is a twenty-four-hour date work. Four cast and turned brass dial feet are pinned to the movement. The cast-brass pulleys are of standard pattern with riveted iron stirrups.

The pendulum rod is round steel with a hexagonal brass nut for pendulum length adjustment. The bob is cast lead with a polished brass face.

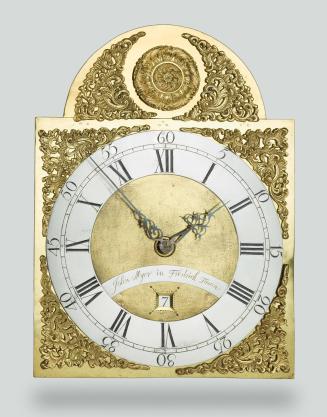

Label TextLike most of Walker's tall clock movements, this one generally resembles British work, but also displays a number of atypical, somewhat unrefined elements that are American. While the cast spandrels may be of British manufacture, the dial, with its many casting flaws and cast-in holes, is clearly an American and probably Fredericksburg production. That Walker made rather than imported his tall clock movements is suggested by the important similarities between the two CWF tall clock movements (accession 1951-578). The pillars, hammers, and decoration on the back-cock of each are identical, and the gathering pallets have unusually long tails. The click springs also mirror one another, an important point since they were invariably produced by the clockmaker, not purchased ready-made. Even the weight pulleys characterized by their long stirrups are the work of a single, probably local, artisan. The British character of Walker's work may reflect training in Great Britian or access to published British sources such as The Elements of Clock and Watch-Work, Adapted to Practice, written by Londoner Alexander Cummings in 1766.

InscribedThe dial is engraved "Thomas Walker / FREDERICKSBURG." A repairer's mark, "J. H. Bates / Oct. 30, 1901," is penciled inside the trunk door.

ProvenanceAccording to family tradition, the clock was originally owned by the Fairfax family of northern Virginia and was given to a member of the Otterback family who worked as an overseer on one of their estates. Census records for Virginia place numerous members of the "Utterback" family in Culpeper and Fauquier Counties, where the Fairfax family had extensive land holdings. The clock descended through the Otterback family to Robert Otterback (d. 1937) of Prince William Co.; to his widow, Lillian Dunnington Otterback (d. 1961); to her niece, Mary Gapen Lanham; to her husband, C. T. Lanham; to his widow, Jane C. Lanham, who, with her stepdaughter, presented it to CWF in 1984.

Exhibition(s)

1765-1785

1814-1825

ca. 1775 (movement); 1805-1815 (case)

ca. 1810

1790-1800

1770-1780

1760-1770

1805-1815

1775-1790

Ca. 1780

1795-1805

1805-1815