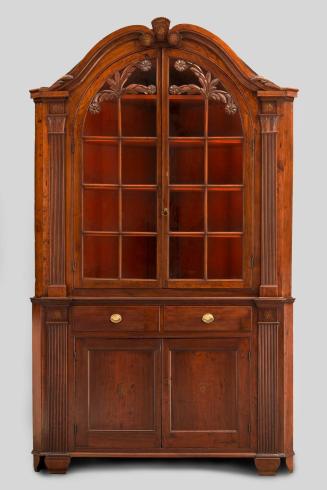

Press or China Press

Date1765-1780

MediumBlack walnut, tulip poplar and glass

DimensionsOverall: 232.4 x 141.6 x 64.8cm (91 1/2 x 55 3/4 x 25 1/2in.)

Credit LineMuseum Purchase

Object number2015-188

DescriptionAppearance: One part press divided into three cupboards; molded cornice around front and sides of flat top; vertical molding applied to front of press at corners; press divided as follows from top to bottom: cupboard with glazed two over two doors with molded mullions with deep scalloped shelf at height of horizontal mullion and shallow straight shelf with molded lower front edge above that; cupboard with two fielded paneled doors with shallow shelf with molded edge and an applied plate rail along bottom of cupboard at back; two shallow drawers each with overlapping fronts and a brass bail and rosette drawer pull; cupboard with two fielded paneled doors and no shelf; all cupboards have brass H hinges, two of which appear to be original on proper left top glazed door; each cupboard opening outlined with scratch bead; integral base molding and straight bracket feet with arch between them on sides and pendant in center of front skirt.

Construction:

The three board top is dovetailed to the sides and rabbeted to receive the ends of the 6 vertical boards that form the back and are nailed to the top from the top. The 3 board bottom is dovetailed to the sides and nailed to the back from the back . All 6 backboards have dados on either side and are joined to each other with a connecting spline, as are the top boards and bottom boards. The two board butt-joined sides are rabbeted at the back to receive the backboards to which they are face nailed. Inside the case, the backboards are beaded on the edges.

The upper front rail is lap-joined and tenoned to the stiles and pegged and nailed to the front edge of the top. The lower front rail is lap-joined and tenoned to the stiles and probably pegged and/or nailed to the front edge of the bottom. The stiles are probably nailed to the edges of the sides (This construction is hidden by the vertical molding that runs up the edge of the front stiles.)

The two piece mitered cornice molding is nailed to the sides, front rail and each other. In the front, a third molding is added to connect with the mitered side moldings that frame the case. That molding (mitered) is under the two-piece molding and extends below it . The side moldings are face nailed to the stiles and are shaped at the bottom to end immediately above the base molding.

The base molding is integral with the shaped front and side feet which are nailed to the bottom, stiles and bottom rail. At the corners, the skirts are mitered at the molding and dovetailed below that to form the front feet. Weight bearing 11” x 4¼” x 2” shaped blocks are fit and placed into the joined front corners, flush with the bottom of the skirt, and extending at a 45 degree angle towards the center of the press and nailed with wrought nails to the underside of the bottom.

A rear lower rail is nailed to the inside of the backboard from the inside (with one wrought nail at each end) and from the back. The rail extends lower than the backboards except for the proper right board with which it is flush. The rail is relieved on the underside except for the ends which are consequently weight bearing. (The proper right end of the rail is replaced.) The side rear bracket feet are nailed into the ends of the rail.

The two medial rails and drawer blade are tenoned and double pegged into the stiles. The vertical drawer separator is tenoned and double pegged into the drawer blade and lower medial rail. A secondary rail is nailed directly behind the full length of the drawer blade. The center drawer support is joined to the secondary rail with one large dovetail, side drawer supports are half-dovetailed and nailed to the secondary rail. All three supports are lap joined to a rear rail that is nailed to the back opposite the drawer blade.

The bottoms and shelves of the two upper cabinets rest in dados (or possibly sliding dovetails) in the sides and are nailed to the back from the back. A side to side triangular lath is nailed to the bottom of the middle cabinet 3½” from the back to create a plate rail.

The openings for each compartment are edged with a scratch bead. The rails of the raised panel doors are through tenoned and double pegged into the stiles. The panels are chamfered on the back edges to fit into dados in the rails and stiles, the inside front edges of which have integral quarter rounds. The rails of the glazed doors are tenoned and pegged into the stiles, as are the horizontal mullions. Integral quarter rounds on the interior edges of the mullions, stiles and rails form rabbets to contain the door glass. Doors for the three cabinets are secured with wooden turn knobs screwed to the case stiles.

Drawers are of dovetail construction with bottoms chamfered on the underside to fit in to dados in the front and sides, and nailed from the underside to the edge of the back. The bottoms are of three butt-joined, front to back grained boards

Woods: Primary wood, including moldings, skirts and shelves are black walnut. All secondary woods are tulip poplar. Drawer fronts are black walnut, sides, backs and bottoms are tulip poplar.

Label TextThis enormous one piece cupboard or press was most likely made by a carpenter or joiner in King and Queen County, Virginia during the second half of the 18th century. Recovered from "Little Plymouth," which is believed to have been built either around 1765 or 1800, this press may have been constructed for that house or one nearby like Clifton (built by John Robinson in 1757). The scale and weight of the piece would likely have disuaded any major moves before the advent of motor vehicles. Little Plymouth has a central hall, two room plan and lacks any beaufaits or cupboards on the first floor. This press with its glazed doors and scalloped shelves was probably used in the parlor/dining room space for display of china. Silver would have been less likely due to the lack of any locks on the piece.

An unusual foot blocking consisting of shaped board nailed to the underside of the bottom from the corner of each foot towards the center of the press at about a 45 degree angle has been seen on another large press in the CW collection (1947-7) attributed to the Southeast, as well as on pieces of 18th century furniture from Litchfield, Connecticut. The Virginia examples may have been a joiner's method of spreading the weight of the extremely heavy case across the case bottom instead of restricting it just to the corners of the piece.

ProvenanceRecovered at "Little Plymouth", King and Queen County, Virginia.

1800-1815

1815-1830

ca. 1830

ca. 1798

1800-1816

1805-1810

c. 1762

1745-1755

1800-1815

1790-1815

ca. 1810

1700-1730