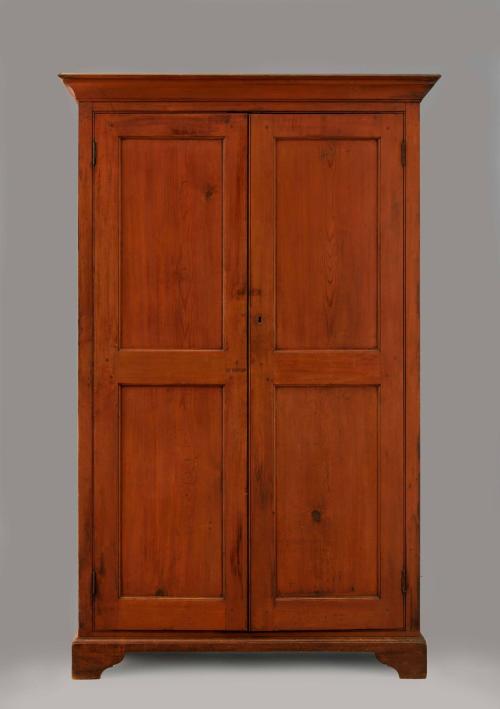

Hanger Press

Date1800-1820

MediumYellow pine

DimensionsOH: 80 3/4"; OW: 51" OD: 21 1/4"

Credit LineMuseum Purchase, The Sara and Fred Hoyt Furniture Fund

Object number2012-87

DescriptionAPPEARANCE: Wardrobe with two double flat paneled doors, coved cornice molding, base molding and bracket feet. Hinged doors open to reveal an open interior with a molded batten attached to the back and sides about 6" from top with eight turned pegs (four now missing) inserted at an angle.CONSTRUCTION: The top is face nailed from the outside into dados in the case sides (the sides extend 4 ½" above the top board), and is butt joined and face nailed to the back assembly and upper front rail. The upper front rail is notched in the lower corners to rest on top of the stiles. The front and rear stiles are nailed to the edges of the sides and extend to the floor. The bottom is chamfered on the underside on the side edges and nailed from the outside into dados in the case sides and butt joined and nailed to the back assembly and lower front rail which is in turn set in notches in the stiles. The stiles and rails are butt joined. Both have an integral bead on the inside edge that is mitered at the corners.

The back assembly consists of five vertical ship-lapped pine boards, the rear stiles that extend the case sides and an interior cross brace. The back boards are nailed into rabbets in the rear stiles. On the inside of the case, a chamfered cross brace is nailed to all five boards of the back. It is lap joined at the crossing, with the upper arms notched on the underside and nailed into notches in the stiles. The lower arms are notched to rest partially on the bottom, notched on the underside and nailed into notches in the stiles. When assembled, the upper arms reach to 16" from the top, and the lower arms extend through the bottom and are sawn off flush with the underside of the bottom.

The underside of the top board at the front center has been relieved to receive a rotating wooden latch which is attached with one screw to the inside of the proper right door, allowing it to turn and secure the door.

The three-piece cornice molding is mitered at the corners and consists of a flat top element that is nailed from below to a middle cove molding that is in turn face nailed to the front rail and sides; with the third element, a lower quarter-round molding, also face nailed to the front rail and sides.

The structural legs are integral to the case sides. They are faced with legs and skirts that are nailed to the sides and lower front rail. The face boards are mitered at the corners and topped with an integral molding.

Inside the case, about 6" from the top, a batten with integral beaded upper and lower edges and butt joined corners is nailed to the back and joined to each side with two (probably replacement) screws. Eight turned pegs are inserted in the battens (four now missing).

The upper, medial and lower rails of the two 2-panel doors are through-tenoned into the stiles with a single peg in the upper and lower tenons and double pegs in the medial tenons. The flat panels are chamfered on their backs to fit into dados in the stiles and rails. An integral beaded astragal edge on the proper left door overlaps the proper right door when closed.

Label TextMost 18th -and early 19th -century Virginia clothespresses have drawer-like trays for the flat storage of clothing. This press features an alternate storage method – pegs for hanging the clothes. Without the interior drawers, this large, hollow cupboard was left with little internal structural support, but the joiner solved the problem with an unusual construction feature that has only been seen in presses from the Caroline County area near Bowling Green—a large X-shaped frame dovetailed just inside the backboards. Like much utilitarian pine furniture, this press was originally stained red.

This press descended in the Hoomes, Maury, and White families of Bowling Green Farm in Caroline County, Virginia. It remained in the house until 2012. Because of its history at Bowling Green, the press can be placed in a specific geographical context—a rarity for such utilitarian furniture. While we may not know the name of the artisan who made this piece, the craftsman most likely worked in the adjacent town of Bowling Green or the surrounding area of Caroline County, Virginia.

ProvenanceDescended in the Hoomes, Maury, and White families of Bowling Green Farm in Bowling Green, Virginia.

Exhibition(s)

1790-1810

c. 1762

ca. 1740

ca. 1830

ca. 1785

1750-1775

ca. 1798

ca. 1810

1800-1815

1710-1740

1765-1780

1760-1780