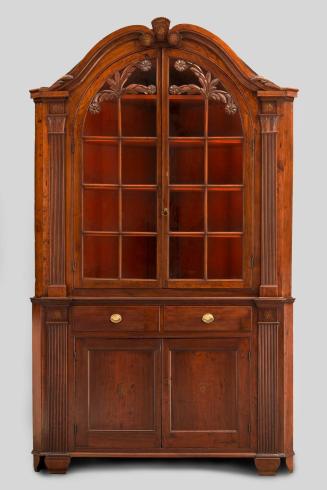

Kast

Dateca. 1798

MediumSweet Gum, black walnut, white cedar, and chestnut

DimensionsOH: 74 ½”; OW: 64 7/8”; OD: 22 1/2”

Credit LineGift of Katharine Bejnar

Object number2017-250

DescriptionAppearance: Three part Kast; dovetailed base with large drawer split by moldings to look like two paneled drawers with center diamond applique and diamond appliques flanking drawer; each paneled drawer front has a centered bail and rosette brass pull; base has a broad ogee base molding and a heavy waist molding at top; two ebonized ball feet with cylindrical bases support front of base; rear square stump block feet; upper case has two raised paneled doors with applied moldings; center pilaster attached to proper left door with oval brass escutcheon above central glyph; doors hang on original iron knife hinges; center and two side pilasters flanking doors have applied capitals and bases and two applied walnut vertical panels divided by a central applied glyph; inside doors are two fixed full depth shelves and one top partial depth shelf; small side-hung drawer hangs on underside of central shelf; removable dovetailed ogee cornice has dado on underside of back rail that sits over the top edges of the case backboards; sides and front of cornice sit down behind Greek key molding applied to front and sides of case.Construction: On the base, the sides are dovetailed to the front and half-blind dovetailed to the back; all are single boards. Rectangular blocks are nailed into the corners from the sides, front and back (nail heads hidden by upper and lower moldings). The rear blocks extend down as feet, the front blocks end at the lower edge of the base and the front ball feet are round tenoned to them. The mitered bottom molding is face-nailed to the sides and front and toe-nailed from the underside to a triangular filler block that is in turn toe-nailed to the sides and front. The upper, overlapping piece, of the mitered top molding is set in a notch in the top corners of the back and nailed from the upper side to the edges of the front and sides. The lower piece of the molding is nailed to the upper molding and to the case front and sides.

The center section of the front has been relieved to accommodate the drawer. Drawer supports are glued and nailed into notches at either end of the resulting drawer blade, and tenoned into the back. The supports are rabbeted to serve as drawer guides. Overhead drawer guides are nailed into notches at either end of the relieved area above the drawer sides and tenoned into the back. Bottom boards that fill the void between the drawer supports and case sides are notched to fit around the corner blocks, nailed to the underside of the drawer supports and toe nailed from below to the sides. Diamond shaped applied panels and surrounding mitered moldings are pegged to the front on either side of the drawer opening and to a 5 ½” x 5 ½” panel nailed (possibly originally pegged) between the drawer’s two paneled drawer fronts.

The drawer is of dovetail construction with the two board (tongue and groove joined, horizontal grained) bottom chamfered to fit into dados in the front and sides, and nailed from the underside to the edge of the back. The drawer is faced with two faux drawer fronts separated by the above mentioned panel. The drawer fronts are edged with mitered moldings nailed to the drawer front. Inside the moldings, a second set of rectangular mitered moldings are pegged to the front and inside those moldings an applied panel, to which the original brass pulls are attached, is pegged to the drawer.

On the case, the stiles are face nailed to the front edges of the sides and the sides are rabbeted on the back edges to receive the back. The stiles are rabbeted on the interior back edge to receive the doors. The upper rail is nailed to the front edge of the sides; a “sister” rail is glued to the back of the rail. The lower rail is nailed to the edge of the bottom and is lap joined to the lower edge of the stiles. A glue block on the underside of the case bottom further secures the rail at its center. Glue blocks also secure the lower edges of the stiles to the underside of the case bottom.

The back is comprised of six vertical tongue and groove joined boards nailed from the back to the three shelves and bottom of the case, which are in turn in a shouldered dado in the sides. The top edge of the back boards are rabbeted to create a tongue that joins with the grooved bottom edge of the cornice back.

The original knife hinges are nailed to the case lower rail and edges of the lower rails of the doors. The upper knife hinges are nailed the edges of the upper rails of the doors and to applied blocks that are in turn nailed to the back of the upper rail’s sister rail. Case shelves are relieved to accommodate the extra room required for doors on knife hinges.

The case’s mitered upper molding is single piece with a Greek key insert. The molding is glued and nailed to the sides and upper rail, with the insert glued in place.

The applied capitals, basses and central glyph of the pilasters on the stiles on either side of the doors are glued and nailed to the panels. The pilaster on the extended panel of the proper left door is the same except that its base is glued and nailed to the lower case rail. The applied moldings and walnut panels of the pilasters are glued and pegged to the panels.

The rails of the case doors are through tenoned and double pegged to the stiles. The door panels are rabbeted to set in dados in the stiles and rails. The moldings framing the raised front panels are rabbeted to overlap the stiles and rails and are glued and pegged to the door panels. They also are slightly chamfered to overlap the angled edges of the mitered raised panels which are solid triangular blocks ¾” thick where they join the center panel. The rectangular central panels are nailed with a top and bottom nails to the door panels with these nails hidden by the mitered molding surrounding the central panel and pegged to it.

The extended panel that overlaps the stile of the proper left (PL) door, (and when closed overlaps the PR door) is nailed from the back to a vertical board that is in turn nailed into a rabbet in the inside stile of the PL door. Upper and lower horizontal boards nailed to the stiles and rails of the door and to the vertical board further secure it. These boards overlap the vertical board and are nailed through fill blocks to the back of the extended panel. The horizontal and vertical boards securing the panel from the back all have integral molded edges. The inside edge of the panel is rabbeted to overlap the PR door and relieved next to the lock which is inset 2” to allow the key escutcheon to be placed in the center of the panel’s pilaster. The inside stile of the PR door is shaped to fit into the relieved area and receive the lock. A toggle screwed to the back of the PR door locks in a gouge on the upper surface of the middle shelf.

The sides of the interior drawer of the case are joined to the overlapping front with sliding half dovetails and to the back with dovetails. The lower edge of the front has integral molding. The single board bottom is chamfered on the underside to fit into dados in the front and sides and is nailed to the edge of the back from below. The sides have front to back dados which slide on two rabbeted drawer supports screwed (modern screws) to the underside of the middle shelf.

On the cornice, the top is comprised of six front to back grained tongue and groove joined boards nailed from above to an inner rectangular dovetailed frame. The front and side edges of the top boards are angled to accommodate the angle of the attached molding. The mitered corners of the single piece ogee molding are nailed to each other and the molding is face nailed to the interior frame and nailed to the top from the top. The underside edge of the frame back is grooved to receive the rabbeted/tounge top edge of the case back.

Woods: The primary wood is gum, with white cedar secondary. Exceptions are walnut inset panels on the case pilasters, and on the base, the chestnut corner blocks and rear legs and ebonized front ball feet.

Label TextKasten or large cupboards such as this were owned by Dutch families in New York, New Jersey, and Connecticut beginning in the mid-17th century. The American kast was based on Dutch Mannerist examples and typically had shelves for the storage of household textiles and clothing as well as a small drawer hung under one shelf. This expensive piece of furniture was typically owned by wealthier families and often was purchased as part of a young woman’s dowry. Family history suggests that this Kast was made around 1798 for Catharine Kip when she was about 17 years old. She married Richard Outwater of East Rutherford, Bergen County, New Jersey in 1812. The names of two of her children, Harriet Eliza Van Horne and Peter Outwater, were inscribed inside the door with the date June 3, 1838, two years after Harriet's own marriage. The kast descended in Harriet's family until acquired by Colonial Williamsburg.

InscribedModern jelly label inside proper left door "Built in the house/ for Katharine Kip/ about 1798".

Pencil inscriptions (TBD) on upper batten on back of proper left door "Harriet E Van Horne/ Peter Out[wa]ter June 3 1838"

ProvenanceFamily traditions suggests that this kast was made for Catharine Kip around 1798. It descended in her family to the donor. Probable line of descent: Catharine Kip Outwater (b. 1782 in New Barbadoes (Hackensack), Bergen Co., NJ.; d. 1850 Boiling Spring (East Rutherford), Bergen Co., NJ; to daughter Harriet Eliza Outwater (b.1817 in Boiling Spring; d.1894 in Jersey City) and Jacob Van Horne (1814-1904); to daughter Harriet Van Horne Maghee (1855-1935) and John Holme Maghee (1851-1925); to daughter Adelaide Holme Magee Marble (1894-1993) and John Putnam Marble (1898-1959); to daughter Katharine Chase Marble Bejnar (1923-present).

The kast was in storage in Orange, NJ from 1935-1955 and then in use by Katharine Bejnar from 1955 until 2017.

1750-1775

ca. 1830

ca. 1775

c. 1762

1765-1780

1705-1715

1700-1730

1815-1830

1800-1815

1800-1815

1760-1780

Ca. 1810