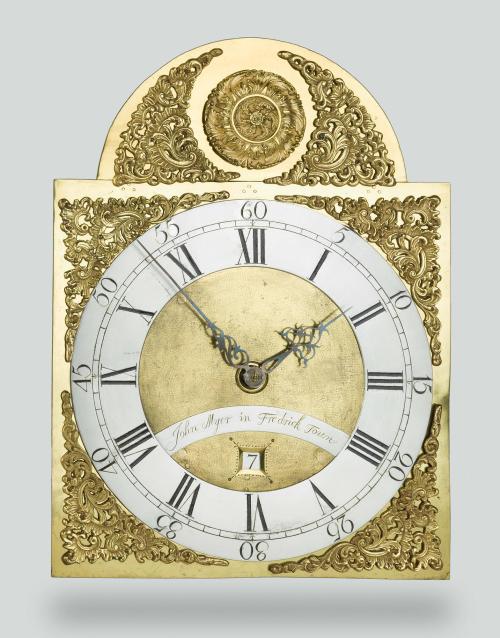

Movement for tall case clock

DateCa. 1780

Maker

John Myer

Mediumiron, brass, and steel

DimensionsOH: 15 1/8"; OW: 13 1/2"; OD: 6"

Credit LineMuseum Purchase

Object number1992-15,B

DescriptionThe clock features a thirty-hour, weight-driven tall case movement with an anchor-recoil escapement regulated by a seconds-beating pendulum. A rack-and-snail striking system sounds the hours on a bell. The eleven-inch cast-brass arched dial has cast-brass spandrels. The hour and minute hands are of blued steel, and there is a date aperture below the dial center. The plates are of cast brass with all surfaces hammered, filed, scraped, and stoned. Four cast and turned brass pillars are riveted to the front plate and pinned at the backplate. The movement is secured to the seat board with hooks over the bottom pillars. The chain pulley on the timekeeping train great wheel is fixed, while that on the striking train is fitted with a brass click work, the clock using Huygen's endless chain system of drive. The tailed steel click is threaded into the great wheel. There is a riveted brass click spring. Some wheels are thicker than usual and have longer than standard epicycloidal teeth. The wheels have four-arm crossings and brass decorative collets. There are cut pinions and slightly convex arbors. The pallets are mounted on a decorative collet. The bent-wire crutch rod is not original. The back-cock is without steady pins. The pendulum has a round brass rod and a four-and-one-quarter-inch brass-faced lead bob. The pendulum nut for adjusting pendulum length is square brass. There is a German-pattern striking system, with the hammer located against the backplate and a combination hammer spring/counter. The four-and-one-half-inch bell is of a non-ferrous metal, possibly bronze, and the bell standard is screwed to the inside of the backplate. The motion work is taken from the extended front pivot of the great wheel arbor. All motion work wheels are uncrossed. The minute and hour wheel pipes are mounted on a start threaded into the front plate. The three-piece dial is made of very thin brass, and the arch and dial center are held together with thin steel strips riveted in place. Four cast and turned brass dial feet are pinned to the front plate. There are blued-steel hour and minute hands, the latter unusually long. The nine-and-one-quarter-pound cast iron weight is rectangular in cross-section and have a cast-in hole to receive the hanging hook. The cylindrical lead counterweight is 2 13/16” diameter x 1 1/16” high. It weighs 2 pounds and has a cast-in wire hook. The movement is driven with a (modern) chain that has a wooden weight pulley with a steel stirrup and a lead counterweight.

Label TextLittle is known about the clockmaker Myer or his career in Frederick. While "Myer" suggests a German heritage, the movement he made for this case exhibits a number of British clockmaking customs. However, many of the movements in clock cases from German-influenced areas of eastern Pennsylvania and the southern backcountry were imported from Britain or made in America in the British style. This pattern suggests that the broad commercial availability of ready-made British clock parts had a strong influence on the nature of local production, even in largely German communities.

Myer's thirty-hour movement is of high quality. Small details like the rabbet cut into the bottom of the bell standard, a time-consuming modification allowing that feature to be steadied where it joins the backplate, is evidence of the artisan's attention to detail. Another sophisticated refinement rarely found on American clock movements is the presence of a wrought safety spring that allows the hands to be turned backward without damaging the moving parts. A sprung rack tail likewise prevents breakage if the clock continues to tick after the strike train has run down.

That the British-inspired movement reflects Myer's work rather than an imported piece is indicated by several structural idiosyncrasies. The click spring is of the sort commonly associated with eight-day movements rather than thirty-hour models. The original join between the main dial plate and that of the arch, a feature of many backcountry southern clocks, may represent an attempt to save on materials. The weights ride on wooden pulleys instead of metal ones and resemble those on other rural clocks. The relatively coarse cast-iron weights may be the work of an iron furnace in western Maryland. Finally, while the date aperture of the dial mirrors those on British clocks from the 1720s and 1730s, the dial plate is extremely thin and matches the construction of late eighteenth-century backcountry examples. Despite its local production, however, the movement includes imported parts such as the chapter ring, Differences between the engraving on the signature plate and that on the ring suggest that the latter was bought ready made from Great Britain.

ProvenanceThe clock was purchased from Richmond, Va., antiques dealer Sumpter Priddy III. He had acquired the piece from Kemble's Antiques in Norwich, Ohio.

Exhibition(s)

1775-1790

ca. 1775 (movement); 1805-1815 (case)

1765-1785

1814-1825

1765-1785

1790-1800

ca. 1810

1795-1805

1805-1815

1805-1815

1760-1770

1770-1780