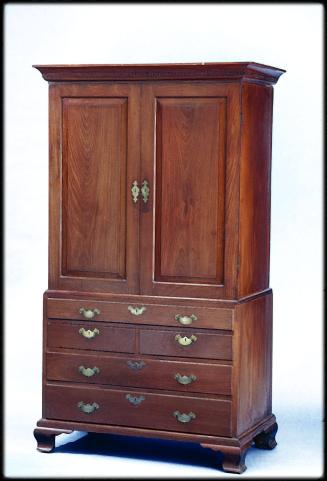

Dresser

Date1790-1810

MediumBlack walnut, tulip poplar, and cherry

DimensionsOH (cornice): 85 1/4"; OH (base): 35 1/4"; OW (feet): 61 1/4"; OD (feet): 19 1/2"

Credit LineMuseum Purchase

Object number1966-485

DescriptionAPPEARANCE: Dresser constructed in one piece; series of molding form bold cornice; base of cornice inlaid at sides and front with a serpenetine line; circular inlays at every other curve of the line formed by the end of a peg, circular in cross section and projecting inside the cornice for hanging objects (pegs do not look original); center front of cornice inlaid with a 4-pointed star flanked by 3 leaves at each side terminating the serpentine line inlay; 2 shelves to dresser and one molded plate rail matching the edge of the shelves above each shelf to support plates; the outer edge of only the lower shelf pierced with 13 key-hole shaped holes for spoons; each side of dresser cut in 3 bold scallops with the top and bottom scallops continuing in a curve to end in a circular terminal; lower part of dresser consists of 3 drawers over 2 doors; center drawer wider than side drawers, each with one original bail-and-rosette pull and framed by inlaid stringing with incurved corners; drawers separated by recessed rectangular panel with molded edges; each door with 2 vertical raised panels framed by inlaid stringing with incurved corners; door secured by 2 (replaced) rat-tail hinges at outer edge and separated by a recessed vertical flat panel with molded edges; one shelf to interior of dresser space; 4 straight bracket feet boldly shaped in outline at each end; applied strips of molding at the back corners of the dresser from top to bottom and at sides and front of lower section; back of dresser made of 4 vertical boards, unfinished at back and nailed in place.CONSTRUCTION: The top is dovetailed to the sides. The four vertical board tulip poplar back is nailed to the edges of the top, sides and bottom. The bottom is dovetailed to the sides. On the upper section, the open shelves are nailed into probable sliding dovetails (possibly dados) in the sides, and nailed to the back from the back. The shelves have integral molding on the leading edge and are notched on each end so that the molding overlaps the edge of the sides. Dish rails have molding that matches the shelves and are chamfered on the back to provide a flat surface for plates. They are face nailed to the sides at either end. The top moldings are mitered at the front corners and are of three pieces that are nailed to each other and to the top and sides.

The top and fixed shelf of the lower section of the case are nailed into dados in the side and nailed to the back from the back. The top additionally rests on the top of the stiles, which have been notched to receive it and is face nailed into the upper edge of the top rail. The stiles are nailed to the front edge of the sides and extend to the floor as do the sides.

The top rail, drawer blade and bottom rail are tenoned and pinned into the stiles, with the bottom rail additionally nailed to the front edge of the bottom. The two drawer dividers are each comprised of two stiles tenoned and pinned into the top rail and through-tenoned and pinned into the drawer blade. The stiles have integral molding on the inner edge which is miter joined to matching applied molding that is glued to the rail and drawer blade, forming frames between the drawers. Flat recessed panels are nailed to the stiles from the back. Behind the panels, boards with rabbets cut on either side are nailed into rabbets in the drawer blade, nailed to the back from the back and function as drawer supports and guides for the drawers on either side. Similarly, boards with rabbets, adjacent to the sides, nailed into rabbets in the drawer blades and nailed to the back to function as the outside drawer supports and guides. A panel between the two cabinet doors is of the same construction as the drawer dividers, with the stiles tenoned and pinned to the bottom rail and through tenoned and pinned to the drawer blade.

The extended sides butt join the stiles to form the functional front feet. The rear feet are formed in the same manner with the extended back joining the extended sides. In all cases, the corner joints forming the feet are strengthened with shaped vertical glue blocks.

The bracket feet, returns and bottom molding are integral and nailed to the functional feet, sides and bottom rail. The side and front sections are joined with open dovetails under miter cut molding to form the front bracket feet, with rear bracket feet nailed to the edge of the back.

A single piece molding is nailed to the front edge of the lower case top, mitered at the corners, and nailed the sides. An additional single piece molding is nailed to the edge of the back at the back edge of the sides to hide the back edges overlapping the sides.

The outer stiles of the two panel doors are notched to receive the rails which are tenoned and pinned to them. Each rail is notched to receive a medial stile which is tenoned and pinned to the rails. On the front of the doors, the stiles and rails have an integral bead on both outer and inner edges. On the outer edge it forms a rabbet that overlaps the case frame when closed. On the inner edges, it secures the raised panel doors. The doors hang on reproduction iron butt hinges.

Drawers are of dovetail construction with one large dovetail in each corner. Bottoms are two board, horizontally grained, butt-joined, chamfered to fit dados in the front and sides, and nailed to the edge of the back. Drawer fronts are walnut, sides back and bottoms are tulip poplar.

Label TextThe dresser was described in 1755 as "The bench in a kitchen on which meat is drest...for the table." Cooking utensils and food were stored below and the table wares bedecked the upper shelves. Produced in the North Carolina Piedmont, this striking example features inlays and shapely upper sides. It is one of the most fully developed dressers known from the early South.

This dresser relates to tall chests, corner cupboards, and clock cases with histories in Alamance and Chatham Counties. All were the work of Quaker cabinetmakers who migrated from Pennsylvania to the Carolina Piedmont begining in the 1750s. Many were related by blood or marriage, and the close-knit nature of their community perpetuated the craft traditions brought from the Delaware Valley.

ProvenanceAcquired in 1966 from Mrs. Raymond C. Power, a Richmond, Virginia, collector of southern furniture. Mrs. Power and her late husband acquired the dresser (and table 1966-487) from Mrs. E. M. Crutchfield, a noted collector residing at Reville, Richmond, Virginia (or possibly from her estate in 1949).

A June 18, 1970, note in the file from Frannk Horton of MESDA states "F. H. owned it for 6 hours. Allamance Co., N.C." On November 17, 1970, Horton gave CWF pre-conservation prints and negatives of the dresser from his own files. A new-looking 1940s Pontiac in the background helps to date the images. A March 1958 article on Virginia Garden Week (Richmond News Leader) shows the by-then fully restored dresser in the collection of Mr. and Mrs. Raymond C. Power. These facts suggest that Horton found the dresser in Alamance County, North Carolina, in the 1940s and sold it shortly thereafter, possibly to Mr. and Mrs. Powers.

Exhibition(s)

1810-1830

1800-1815

1815-1830

1760-1780

1750-1775

ca. 1740

1800-1815

ca. 1798

ca. 1775

1705-1715

1765-1780

1805-1810