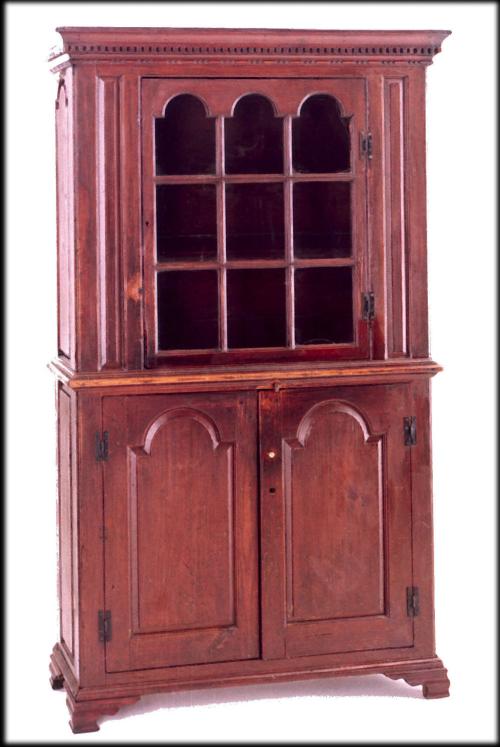

China press

Dateca. 1790

MediumYellow pine and glass

DimensionsOH: 81" OW (top): 49" OD (top): 20 1/2"

Credit LineMuseum Purchase

Object number1936-752

DescriptionApperance:China press in one piece; flat rectangular top surrounded on three sides by board, cove cornice above a band of carved dentils, below dentils is a narrow carved band of bead and reel molding; the upper half of the front is composed of a single glazed door flanked by a pair of narrow, rectangular field panels; the door is composed of nine glazed panels arranged in three rows of three, the panes divided by molded mullions, the three upper panes arched at top; door is hinged at right on two replacement butt hinges, opens to reveal plain interior with two, full-width shelves; sides of upper section each composed of a single arched, fielded panel; upper section of cupboard separated from lower by a broad band of step molding on three sides; front of lower section composed of a pair of doors, each with a single arched, fielded panel; doors open at outside on butt hinges, to reveal plain interior with braces for two shelves (shelves now missing); sides of lower section composed of single rectangular fielded panel; step base molding on front and sides above short ogee bracket feet (replaced).

Construction:

The one piece flat-wall Eastern Shore cupboard is constructed entirely of yellow pine with wooden pins and cut nails. The two board top is nailed into rabbets in the corner stiles, upper side rails and top front rail. The front-most side panel stiles are fitted into rabbets cut in the front stiles and nailed in place from the face of the front stiles to form corner stiles. The integral thumbnail molding of the edge of front facing stile provides the case with slightly chamfered and molded outside front corners. Both front and back stiles originally extended from the top through the bottom of the case to the floor. They supported the case and the original feet would have been nailed to them. When the bracket feet were replaced, the front and back case stiles were sawed off even with the lower edge of the bottom front rail and replaced with modern blocks which now support the case. The replacement ogee bracket feet are glued and nailed to those blocks.

The top, medial and bottom rails are tenoned and pinned into the stiles. The interior stiles on either side of the upper (glazed) door are tenoned and pinned into the top and medial front rails. Lath 1/8” x 1” is nailed to the back side of the proper right interior stile and extends ¼” beyond it to form a stop for upper door. Lath 7/8” x 3/8” is nailed to the back of the medial rail and extends i/4” below the edge to form a stop for the lower doors.

All raised panels are beveled on the outside edges to fit into dados the stiles and rails. All rails and stiles have integral thumbnail moldings.

The back is comprised of seven horizontal lap-joined boards nailed into rabbets in the side stiles and face nailed to the edges of the bottom and the top

The front and side bottom rails extend about 1” below the underside of the bottom and are probably nailed to the edges of the bottom. Modern supports have been nailed to the side rails underneath the bottom. Three modern boards running front to back have been screwed to the underside of the bottom for additional strength.

Supports for the floor of the upper cabinet are nailed to the stiles and medial side rails and the floor is in turn nailed to the supports. Shelf supports in both the upper and lower case are nailed at each end to the side stiles. The two shelves in the upper case are removable. Modern strips have been nailed to the floor and shelves 2” from the back to facilitate display of plates. The two removable lower case shelves are missing.

The mitered crown molding is comprised of multiple pieces. A cove molding over a dental molding are both nailed to a backing molding with a smaller cove at its bottom edge. Under that assembly, is a narrow carved band of bead and reel molding. The backing molding and the narrow molding are nailed to the upper rails and upper edge of the stiles. The two piece mitered step waist molding is nailed together and to the front and side rails and stiles as is the mitered single piece foot molding.

On the glazed upper door, the rails and the horizontal mullions are tenened with pins to the stiles; vertical mullions are most likely tenoned into them. Panes rest in rabbets in the stiles, rails and mullions and are held in place with small nails and glaze. All nine panes are rectangular, with deep rabbets cut in the arched top rail to accommodate the top row of panes.

On the raised panel lower doors, the rails are through-mortised and double pinned to the stiles. The arched panels are of the same construction as the case panels. The inside stiles of the doors are ship-lapped with a wooden turn latch over the proper left door to secure the doors shut.

Upper and lower doors are attached with nailed replacement “H” hinges.

MarkingsNone found

ProvenanceThe source and history of this piece is unkown; it apparently was purchased locally.

1800-1815

1745-1755

1790-1815

ca. 1830

1810-1835

1765-1780

1800-1816

ca. 1750

1815-1830

1815-1820

1820-1840

1705-1715