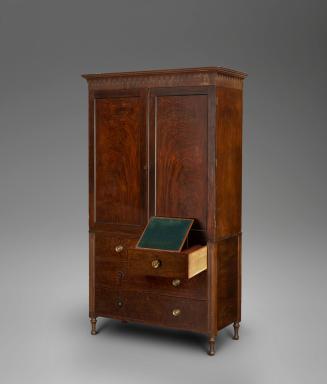

Secretary and bookcase

Date1705-1715

OriginEngland, London

MediumPrimary: Burl walnut veneer and walnut on oak; Secondary: oak framing.

DimensionsOH: 81"; OW(base): 41"; OD(base): 15 3/4"

Credit LineMuseum Purchase

Object number1956-343

DescriptionAppearance: Secretary and bookcase: flat top surrounded on three sides by broad, cove molding, with narrow molding below; straight sides; front composed of a pair of doors each with large, rectangular bevelled mirror glass panel surrounded by half round molding; right door has strip of molding at left side; pair of small, oval, brass escutcheons, one on each door at center; doors open to reveal interior fitted with slots on each side, and three adjustable shelves; pair of candleslides below doors on exterior of front, each with single brass knob at center. Lower section: flat, recessed top surrounded by complex molding on front and sides; cross-banded panel at front, with central, oval escutcheon, falls down and section behind pulls out to reveal fitted secretary interior; large pigeonhole above a drawer on each side, separated from center section by high divider with scalloped upper edge; center section contains nine drawers arranged in three rows; interior of fall front surface lined with green velvet; broad molding below desk section on front and sides; pair of large cupboard doors below, each with oval escutcheon, open to reveal slotted interior; broad base molding; desk rests on four, flattened ball feet (replaced).Construction:

The two board oak top is dovetailed (construction hidden) to the single board sides (oak with book-matched veneered walnut). The sides are in turn dovetailed to the two board oak bottom. The veneer extends below the sides and covers the side rails of the support frame below the bottom.

The bottom’s support frame is comprised of three miter joined oak rails with the side rails positioned under and glued to the bottom edge of the sides and the front rail glued to the front facing edge of the bottom. An 8” chamfered medial glue block further supports the joining of the front rail and case bottom. Mitered chamfered corner glue blocks in the front corners of the frame and chamfered rectangular glue blocks on the inside back of the side rails further secure the frame to the case bottom and correspond to blocks on the top of the lower case which support the weight of the upper case. The front and side edges of the front rail are walnut veneered.

The upper front rail is nailed to the top from the top. A chamfered oak board is nailed to it on the inside face of the rail and extends down past the rail to form a rabbet which acts as a stop for the case doors.

The lower front rail is relieved for two candle slides each of which slide in rabbets in chamfered oak supports that are glued and nailed to the underside of the case bottom. The bottom of the oak candle slides is comprised of a side-to-side grained board butt joined to a front-to-back grained board, both oak. The miter joined sides are glued to the upper surface of the bottom. The walnut veneered front is miter joined to the sides, and rabbeted on the underside to overlap the bottom when closed. The slot in the front rail that receives the candle slide is rabbeted along the bottom edge to catch the slide's rabbeted front so that the slide is flush with the case front when closed. A full width stop is nailed to the underside of the slide bottom at the back.

Slots for movable shelves are formed by 21 oak battens (1” x 11” x ¼”) glued on each interior side. The three oak shelves, with rounded front edges (one single-board and two 2-board), appear original.

The back is comprised of five oak boards, the widest of which has split due to shrinkage, nailed (some wrought) and screwed into rabbets in the sides and to the edge of the top and bottom.

The multi-piece top molding is comprised of a deal, walnut veneered cove molding to which are attached two oak moldings, both faced with walnut. A smaller additional walnut faced molding is glued to the case side directly under the large cove molding.

The rails of the mirrored doors are tenoned into the stiles. The backs and inside edges of the stiles and rails are veneered with cross grained walnut and on the front with figured walnut. The side facing edges of the doors are veneered with walnut. The mirror panels are hand beveled, backed by oak panels and secured in the back with mitered oak quarter rounds nailed (mixture of early and possibly modern nails) to the interior edges of the rails and stiles. In front the panels are secured with mitered deal faced with cross grained walnut quarter rounds and glued to the stiles and rails. A shaped walnut molding is glued to the edge of PL (proper left) door to overlap the PR door. The door rails are joined to the upper and lower front rails with recessed knife hinges. The door lock is original as are the sliding locks on the PR (proper right) door.

Note: All cross-grained walnut veneer and moldings on upper and lower cases are applied in sections to minimize shrinkage losses.

Lower case

The three board (butt joined) top is dovetailed to the single board oak sides (construction hidden). The four horizontal board (oak) back is nailed into rabbets in the sides and to the edge of the top and bottom with wrought nails. Oak lath is glued to the underside of the top at the front and side edges where it butt-joins the sides. The top of the secretary drawer abuts the lath to avoid tipping when opened.

The three piece mitered molding at the top of the lower case, as well as the belt and base moldings, consist of deal faced with shaped walnut. The lower section of the upper molding overlaps the sides and front and is glued to them. The cross grained middle section is glued to the top of the sides and the interior most section, which functions to secure the upper case, is glued to the upper surface of the top and to rectangular glue blocks at each corner which are also glued to the top and support the upper case.

The fixed shelf upon which the secretary drawer rests and slides is joined to the sides with probable sliding dovetails and/or dados. The shelf is rabbeted on the underside of the front edge to receive the case doors. The mitered belt molding is glued to the front edge of the shelf immediately above the rabbet and to the case sides. Under the shelf are ten slots for moveable shelves formed by applied oak battens identical to those in the upper cabinet.

The two board bottom is dovetailed to the sides (construction hidden) and is rabbeted to receive the doors. Mitered deal boards (1”x 2”) are glued to the underside of the bottom at the edges of the front and sides forming a frame which is supplemented with additional oak blocks at the corners to provide a surface to support the pressed ball feet. The dowels of the feet (replaced) are secured in holes extending through the blocks and bottom. The mitered base molding (deal faced with shaped walnut over cross-grained walnut) is glued to the edge of the bottom frame.

The single board sides of the secretary drawer are probably dovetailed to the single board bottom and single board top. The back is nailed into rabbets in the sides and bottom and glued to the underside of the top. The fall board consists of a single board with end battens and a rabbet on the bottom edge corresponding to a rabbet on the underside of the writing surface which interlock to support the fallboard when open. Pegs in the front edge of the fixed writing surface correspond to drilled holes in the edge of the fallboard to keep the boards in plane when open. The fallboard and writing surface are joined with inset brass hinges. The fallboard is figured walnut veneered with chevron edging on the front surface and walnut veneered with cross-grained veneer in front of the velvet surface on the inside.

The walnut faced oak drawer blades, dividers and shelves of the secretary drawer interior are dadoed into the drawer sides, surface and top, and each other. Thin walnut runners for the drawers resting on the writing surface are glued to that surface as is the inset (early but probably not original) velvet writing surface. Small drawers are of dovetail construction with bottoms nailed and glued into rabbets in the fronts and set in rabbets in the sides and backs which are nailed to the edges of the bottoms. Drawer bottoms, sides and backs are oak. Drawer fronts are oak with book-matched walnut veneer edged with chevron.

Below the secretary drawer, the doors of the lower compartment are comprised of four vertical butt joined slats (identified due to shrinkage) probably tenoned into oak end battens. The doors are book-matched walnut veneered with mitered cross-grained edging on the back of the doors and herring bone edging on the front. The top and side edges of the doors are veneered in walnut. A shaped walnut molding identical to that on the upper door is glued to the PL door to overlap the PR door. The doors are joined to the case rails with recessed knife hinges. Desk and door locks appear original as do the key escutcheons.

Label TextWhile slant front desks were quite popular, an option was a secretary drawer like the one on this piece. The front of the drawer hinges open to form a writing surface with the writing compartment fitted into the drawer interior that can slide forward for use. Mirrored bookcase doors reflected light, especially when candles were placed in the slides in front of those doors. MIrrored case pieces like this were often placed on architectural piers, between windows, where pier glasses might otherwise have been situated. Both were chosen to reflect light around a room.

InscribedIn chalk on top of lower case "PHILLIPS"

MarkingsThree locks stamped "9292, 9294, 9295" Cloth tag in drawer reads on one side: "The Lady C. Ashburnham/ London/ Taverstuck/ Via Boulogne...mer/ Via Boile". On reverse reads: "Key of Walnut Bureau with glass doors/ Philips of Hitchen, The Manor House, Hertfordshire, Eng". Printed on tag on back of lower case "PHILLIPS OF/ HITCHIN LTD".

ProvenanceEx coll: Ashburnham Place, Sussex.

ca. 1775

1700-1730

1740-1755

ca. 1810

ca. 1740

ca. 1785

ca. 1798

ca. 1830

1800-1815

1810-1820

ca. 1800

Ca. 1810