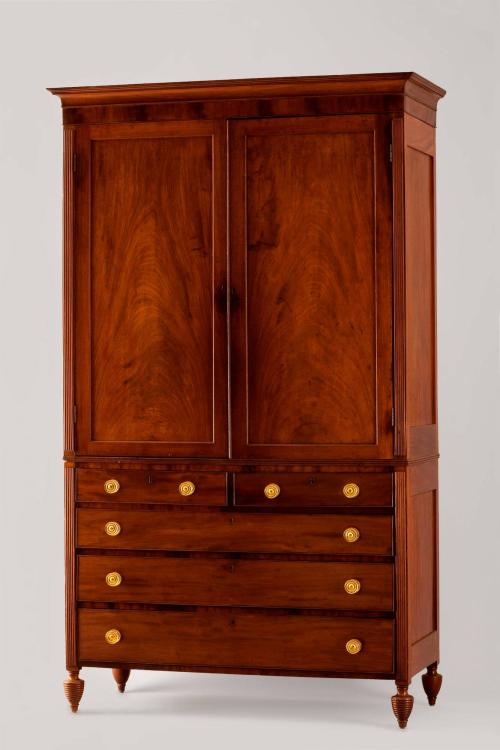

Clothespress

Date1821

Maker

James Woodward

MediumMahogany, mahogany veneer, yellow pine, tulip poplar, and brass.

DimensionsOH: 92 5/8"; OW: 55 5/8"; OD: 23 7/8"

Credit LineMuseum Purchase, The Sara and Fred Hoyt Furniture Fund

Object number2010-115

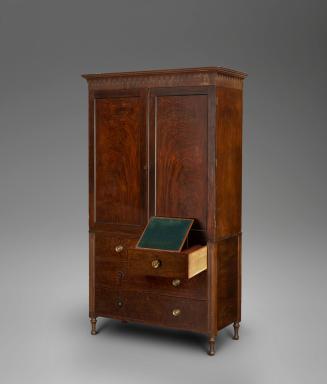

DescriptionAppearance: Clothespress in two parts. Upper case consists of two flat paneled doors flanked by applied five-lobed reeded pilasters surmounted by a frieze of cross banded veneer and topped with a detachable molded cornice. Interior of upper case consists of four clothing trays with shaped fronts and rounded sides supported by drawer supports dadoed and nailed into boards screwed to interior of case sides. Exterior sides of both upper and lower cases have flat panels. Lower case consists of two drawers over three larger drawers divided by drawer blades with cross-banded veneer and flanked by applied five-lobed reeded pilasters. Urn-shaped front and back feet are extensions of the stiles with applied lamination on four sides. Front feet have ring turnings creating a "beehive" appearance. Both upper and lower cases have paneled backs.Construction: On the cornice, the sides are dovetailed to the back. Vertical blocks reinforce the front corners and hide probable front dovetails. Cross-banded veneer on the front and both sides is topped with a one-board molded cornice that is glued and nailed in place with a triangular block filling the void between the angled molding and frame.

A 5" block (now broken) is nailed to the backside of the front with a corresponding screw hole in the top of the upper case enabling the cornice to be held in place. Two modern lath braces are dovetailed into the bottom edge of the front and back and parallel to the sides. They serve to stabilize the cornice and are used to screw the cornice to the top of the upper case.

Cock-beaded lath is nailed to the bottom edge of the front and sides.

On the upper case, the single board top is dove-tailed to the front and back stiles and nailed into rabbets in the side rails. Mahogany lath is nailed to the front edge of the top, which is exposed when the doors are opened. The rails of the single panel sides are tenoned into the case stiles forming a frame for the flat panels. The panels (probably chamfered in back) float in dados in the stiles and rails. Five-lobe reeded pilasters are glued to the front of the front stiles (one appears up-side-down).

The stiles of the two-panel back assembly are nailed into rabbets in the case stiles and to the edge of the top. The rails of the assembly are tenoned into those stiles and a medial stile is tenoned into the rails. The back of the panels are chamfered to float in dados in the stiles and rails.

Like the top, the bottom is dovetailed to the stiles and nailed into rabbets in the side rails. Three-lobe reeded mahogany lath is nailed to the underside of the bottom at the front and sides and supports the weight of the upper case.

Inside the upper case, full height and width interior sideboards are screwed into lath strips (three on each side). The strips extend from front to back stiles and are set in notches in the stiles. The function of these strips appears to be to keep the interior sides from sliding out when the trays are pulled out. Additionally, the PR interior board is nailed to the bottom, and both are nailed to the case stiles at the top. Three holes in the bottom (center and both sides) enable the upper case to be secured to the lower case with screws. Tray supports are nailed to the sides with the sides functioning as guides.

Rails of the single panel door frames are through tenoned into the stiles. Book match panels are slightly chamfered in back and float in dados in the stiles and rails. The beaded astragal is glued and nailed to the edge on the PL door and overlaps the PR door when closed. The PR door has a sliding door latch at the top with matching notch in the top rail; there is evidence of a missing matching latch on the bottom of the door.

Clothing trays are of dovetail construction with horizontally grained bottoms chamfered to fit into dados in the front and sides and nailed to the bottom edge of the back. Blocks (2 ½"), butt joined to each other and glued to the bottoms and flush to the drawer sides, serve as runners.

On the lower case, the front top rail is dovetailed into the stiles; the rear top rail is tenoned into the stiles. The top is flush with and butt joined to the front and rear top rails, and face nailed into rabbets in the upper side rails and into blocks that are glued into each corner and rest on the top drawer guide rails. The top is comprised of two butt-joined boards, with the second board pieced-in at the back to adjust for the fact that the primary board is not square.

Top and bottom side rails are tenoned into the stiles forming a frame for single flat panel sides that are slightly chamfered on the back and glued into dados in the stiles and rails. As with the upper case, five-lobe reeded pilasters are glued to the front of the front stiles.

The back is comprised of two panels each of which is made up of two tongue and groove joined boards. The panels are chamfered in back and float in dados in the bottom rail, the stiles and a 15½" wide medial stile. One panel on each side is nailed to the upper rail, with the other unsecured. The upper and bottom back rails are tenoned into the case stiles. The rear face of the upper back rail is chamfered on each end to align with the dados in the back stiles. The medial stile is tenoned to the bottom rail and nailed to the top rail.

The lower case has no bottom. Drawer blades are tenoned into the stiles. A medial drawer divider is double-tenoned into the top rail and drawer divider. A panel is tenoned to the back of the drawer divider and extends the divider to the back where it is butt joined and nailed from the back to the back. Above the extended divider, lath is nailed from above to the underside of the top. Beneath the extended drawer divider, the single board runner for the top two drawers is tenoned into the top drawer blade and nailed to the back. A drawer guide is nailed from below to the top of the runner.

Remaining drawer guides float in notches cut in the front stiles that extend downward so that the drawer blades block the guides from pulling out. In the back, the guides float in similar rabbets and are held in place by drawer stops nailed to the stiles. A block is glued to the case side behind the center of each drawer guide to keep it from warping towards the side. Drawer supports are nailed to the lower portion of the drawer guides. The bottom side rails function as drawer guides for the bottom drawer, with drawer runners nailed to the rails. Bottom drawer stops are glued in the corner formed by the back rail and stiles.

The feet are urn shaped with the front feet reeded to simulate an inverted beehive. The feet are extensions of the stiles with four pieces glued up and then turned.

Drawers are of traditional dovetail construction with horizontal grained bottoms chamfered to fit in dados on the front and both sides and nailed to the back from the bottom. Full width drawers are of the same construction but with two panels dadoed into a medial rail that is butt joined and glued to the front and nailed from the bottom to the back. A 1-2" block is glued to the underside of each bottom panel of the full-width drawers at the center-front edge. Modern full length runners are glued at the junction of the sides and bottoms of all drawers. Cock beading is nailed on drawer edges.

Label TextThis clothespress is one of only a few pieces of furniture signed and dated by the Norfolk, Virginia cabinetmaker James Woodward. Woodward was the most prominent Norfolk cabinetmaker in the first half of the 19th century, advertising “elegantly finished” furniture made by “the best workmen from Philadelphia and New York, and from Europe.”

The clothespress, which has sliding trays in its upper section for the storage of clothing and other textiles, was a British form. Its particular popularity in the American South reflects the influence of contemporary British styles brought over by immigrant cabinetmakers, as well as the southern consumers’ desire for fashionable English furniture forms. Well established Northern cabinetmakers and buyers were not as impressed by fluctuating English furniture fashions and consequently favored the older high chest form over the clothespress.

A few years before this press was constructed, James Woodward freed a thirty-eight year old enslaved journeyman cabinetmaker named James by a deed of emancipation. Woodward had entered an agreement in 1817 with James’s former enslaver, Elizabeth Bailey, widow of cabinetmaker Richard Bailey. Woodward paid Bailey $120 for James and agreed to emancipate him after one year of work in Woodward’s cabinetshop, the equivalent of $120 in wages. Woodward’s incentive to emancipate James is unknown, but perhaps the men had a prior connection or perhaps the connection was between Woodward and the Baileys. The way that the documents are worded suggests that Woodward loaned the initial $120 to James to purchase his freedom from Elizabeth Bailey and that James' labor for one year, equivalent to $120 in wages, repaid Woodward for the loan. However, other documentation suggests a bill of sale between Bailey and Woodward for James.

James appears to have remained working for Woodward for at least a few years after his emancipation as one “free colored” male between the ages of 26-44 (James would have been 40) appeared on the 1820 census in Woodward’s household. Fourteen other enslaved individuals also appeared in Woodward’s household in that year, including two men who may have worked in the shop.

InscribedInscribed in chalk on the inside of the upper case backboard panels "Woodward", and "1821" within a flourish.

Exhibition(s)

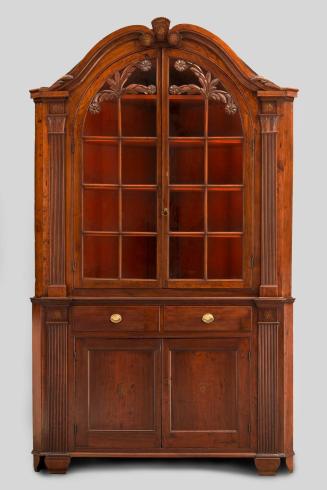

ca. 1740

1700-1730

1750-1775

Ca. 1810

ca. 1798

1800-1815

1710-1740

1810-1820

ca. 1830

1840-1850

1800-1815

1760-1780