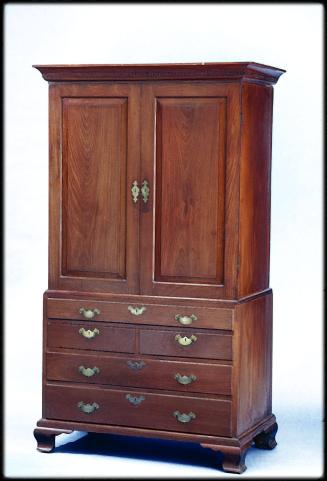

Clothespress

Date1765-1775

MediumBlack walnut and yellow pine.

DimensionsOH: 54 7/8" OW: 49 1/2" OD: 22 1/2"

Credit LineMuseum Purchase

Object number1950-350

DescriptionAppearance: Clothespress with two full-height doors, each with two raised panels and a single escutcheon (blind on left door); molded edge on top board; quarter-round base molding; straight bracket feet; interior with three fixed shelves, one sliding clothes tray, and two drawers; bottom shelf (above drawers) faced with black walnut; clothes tray with shaped side boards and no front board. Construction: The bottom is dovetailed to the case sides, while the top, with its integral front and side moldings, runs on sliding dovetails. The back consists of four horizontal butt-joined boards nailed into rabbets along the top and sides and flush-nailed at the bottom. The doors exhibit standard through-tenoned panel and frame construction without joint pins. The base molding is set against solid glue blocks that run the full width of the front and sides and extend in along the back just far enough to support the rear feet. The intersections of these blocks are reinforced with triangular blocks of the same thickness. Stacked horizontal glue blocks back the mitered bracket feet. The three fixed interior shelves are joined to the sides of the case with sliding dovetails that stop short of the front edges. The drawer divider is tenoned into the lower shelf and the bottom board and is backed with a half-height yellow pine rail set into a dado in the bottom board.

The single clothes tray features side and backboards dovetailed at the rear corners. The back of the tray is nailed to the rear edge of the bottom, and the bottom is nailed to the lower edges of the sides. The tray is supported on the projecting side edges of its bottom board, which runs in dadoes cut into the sides of the case. The dovetailed drawers have flat bottoms nailed into rabbets along the front and sides and flush-nailed at the rear. They are further supported with full-length glue blocks along the front and sides that are butted at the front corners and mitered at the rear. The drawers run directly on the bottom board.

Materials: Black walnut top, sides, doors, base molding, exposed parts of feet, rear faces of rear feet, drawer fronts, drawer divider, and bottom shelf facing; all other components of yellow pine.

Label TextThe Chesapeake's preference for the clothespress was probably due in part to the uneven rates of urban growth in the colonies. In the South, most cities remained too small to support full-time cabinetmaking communities until the 1720s, but as towns like Annapolis, Norfolk, and Charleston grew during the second and third quarters of the eighteenth century, they attracted furniture makers recently trained in Britain. These new arrivals brought an up-to-date knowledge of British tastes in household furnishings including forms like the clothespress. Conversely, urban centers in the North were already well established, and large furniture-making communities there were more resistant to the influences of immigrant British artisans. As a consequence, the gentry in places like Boston, Newport, and Philadelphia retained their preference for the earlier high chest of drawers and accepted newer goods like the clothespress less readily.

Because most apparel was still folded for storage during the eighteenth century, the clothespress was provided with shelves or sliding trays designed for easy access. The Virginia press illustrated here, which has three stationary shelves, a single sliding tray, and two interior drawers, represents one of the most basic versions of the form. Much smaller than the average southern press, it lacks the usual bank of exterior drawers in the base. Despite its simplicity, the press exhibits the same careful attention to detail that marks most other furniture made in urban eastern Virginia at the end of the colonial period. The mortises and tenons at the corners of the door frames were cut with great precision so that visually intrusive end-grain pins were not required to keep the joints tight. The bracket feet are supported on stacked, horizontally grained blocks instead of the vertical blocking found on most other American furniture. This time-consuming technique allows the blocks and the horizontally grained bracket faces to expand and contract harmoniously as the temperature and relative humidity change, thus providing a structural unit that is more stable and more likely to survive intact. These and other construction details reflect the urban British craft traditions introduced by immigrant artisans.

Made in Williamsburg during the 1760s or 1770s, the press has a history of ownership in the Galt family. It is one of several locally made case pieces that display similar molding profiles and remarkably consistent drawer, door, foot, and base molding construction, which strongly suggest production in a single shop. Related objects include a desk and bookcase originally owned by Williamsburg physician John Minson Galt (1744-1808) (CWF acc. 1950-349), and another clothespress that descended in that family (CWF acc. 1950-351). At present, these pieces cannot be firmly attributed to a specific craftsman, but in view of their histories and overall decorative and structural relationship to other Williamsburg products, there can be little doubt that they were made by one of the eleven cabinetmakers working in the colonial capital at various times during the third quarter of the eighteenth century.

InscribedSeveral possibly early columns of mathematics are penciled on the upper backboard.

MarkingsNone.

ProvenanceThe press descended through the Galt family, residents of Williamsburg since the eighteenth century, to Mary Ware Galt Kirby, who sold it to CWF in 1950.

1805 (dated)

1760-1780

ca. 1740

1700-1730

Ca. 1810

1820-1830

1804-1813

1750-1775

1750-1760

ca. 1750

1795 (documented)