Sideboard

Date1810-1820

Signed by

William Moss

MediumMahogany, yellow pine, and tulip poplar

DimensionsOH: 52 1/8"; OW: 78 5/8"; OD: 26 1/8"

Credit LineMuseum Purchase

Object number2001-763

DescriptionAppearance:A large sideboard on six turned legs of tripartite design composed of three cabinets, the central one bowed with double doors, interspersed with deep bottle drawers below a tier of five shallow drawers of different widths symmetrically arranged, and further below drawer cases affixed to each end of the top of the sideboard and linked across its back with an arched splashboard.

Construction:

The sideboard is comprised of three cabinets, joined together by the back which is comprised of two butt-joined horizontal yellow pine boards tenoned into rear mahogany stiles. The single board mahogany sides are tenoned into front and rear stiles. Case separators between the cabinets are tenoned into two interior front stiles and through-tenoned into the back. The four corner stiles and two interior front stiles are integral with the turned legs and small diameter feet which are capped with brass casters. All exposed surfaces are of mahogany veneer except those noted as solid magogany.

The ¼” mahogany top is glued to a frame consisting of a back rail tenoned into side rails, two interior rails tenoned to the back rail and joined to a three-section front rail shaped to match the shaped front edge of the top. The side sections of the front rail are miter-joined and tenoned into the side rail, and tenoned into the two interior rails into which the miter-joined center section is also tenoned at the intersections of its middle and side sections.

The top frame is screwed to the case from pockets in the back, to the sides and to the front rails of the center and side cabinets from the underside.

On the center section, the 2” thick (2 laminated 1” boards) yellow pine top rail, drawer blade and bottom rail are double-tenoned into the interior stiles. All three are shaped to match the top. The upper drawer separators are double-tenoned into the top rail and drawer blade and the lower separators into the drawer blade and bottom rail. Behind the drawer blade under the side drawers are full depth dust boards that extend 1½” underneath the center drawer to function as drawer supports for it as well. The dust boards/supports are tongue and groove joined to the drawer blade and nailed to the back from the back. Drawer guides are in turn nailed to them directly behind the drawer separators.

An additional drawer guide, to prevent tipping when the drawer is open, is centered above the drawer, tenoned into the top rail and nailed to the back from the back. Rectangular drawer stops are glued to the back above the center drawer guides and behind the bottle drawers. Drawer guides for the bottle drawers are tongue and groove joined to the drawer separators, nailed to the back from the back and to the bottom from the underside.

Arched brackets below the bottom rail are glued to the bottom-most rail and to the interior legs with shaped glue blocks. The bottom-most board of the back is shaped to match the arched brackets and is joined to the case separators with glue blocks.

The single board (tulip poplar) center case bottom is supported by closely spaced rectangular blocks that are glued and nailed to the back, case separators and back edge of the front rail. A single nail from the back into the back edge of the bottom adds additional support.

On the side sections, the 2” thick laminated yellow pine top rails are double-tenoned into the stiles as are the drawer blades and bottom rails. Drawer guides are glued to the side and interior case separators; drawer supports are nailed from the underside to the bottom edge of the drawer guides. An additional drawer guide is nailed to the upper edge of the outside drawer guides to keep the drawers from tipping when open. Supports for the cabinet shelf are nailed to the sides.

The single board bottoms of the side sections are butt joined to the front rail, nailed from below to the bottom edge of the back, nailed from below into rabbets in the sides and chamfered and nailed from below to the bottom edge of the case separators.

On the drawer boxes setting on each end of the top, the sides are dovetailed to the backs and probably tenoned into the front stiles which are in turn probably tenoned into the front top and bottom rails. Drawer supports are glued and nailed to the sides and in turn screwed to the case top. The top, with, with integral triple-beaded edge, is joined to the sides with a series of glue blocks and to the front and back with single glue blocks. Rectangular drawer stops are glued and nailed to the sides. Between the boxes, the shaped mahogany back panel is lap joined and screwed to the inner back edge of the two boxes and butt joined to the upper surface of the top. Triple beaded molding that matches the edge of the tops of the boxes is applied to the top edge of the panel.

Triple beaded molding is applied to the front facing bottom edges of the case.

The center cabinet doors are comprised of curved yellow pine boards tenoned into walnut stiles on each side, with the front surface veneered and cock-beading on the edges. The yellow pine boards are stained on the back (interior) surface to match the walnut stiles. An interior brass sliding door pin secures the proper right door, and square door stops are glued to the upper surface of the bottom rail behind each door.

The rectangular doors on each of the side cabinets are of the same construction (although not curved). The veneer on the side cabinet doors however consists of an arched mahogany center panel framed with cross grained mahogany.

The drawers are of tulip poplar with mahogany fronts with applied cock-beading. They are of typical dovetail construction with the underside edge of the front and side edges of the bottom chamfered to fit into dados in the front and sides of the drawers. The bottom is nailed from the underside to the edge of the back.

The bottle drawers have bottle separators set in dados in the drawer sides. The center drawer is fitted with modern interior dividers that are joined with glue and wire nails.

Label TextThe William Moss who signed this sideboard, presumably as its maker, was likely the free Black man of that name who lived in Lynchburg, Virginia between at least 1814 and 1820. While that William cannot be documented as a cabinetmaker, he is the only known man of that name to have been in Campbell County, Virginia between 1800 and 1820, the likely years when this sideboard was produced.

The sideboard descended in the Craddock or Gilmer families of central Virginia and Lynchburg. The accomplished quality of the woodworking, particularly in the manipulation of the matched veneers to create a complex pattern, demonstrates Moss' considerable skill as a cabinetmaker.

InscribedInscribed on bottom of drawer: "William Moss/ his hand".

"H.C. '18.....{indecipherable}"

ProvenanceThe sideboard belonged to Charles Granville Craddock of Lynchburg in the early 20th century and had descended in his family. They sold the house with the sideboard to the parents of Mrs. Fairfax and Mrs. Lewis. (Notes by Phil Zea, 2001)

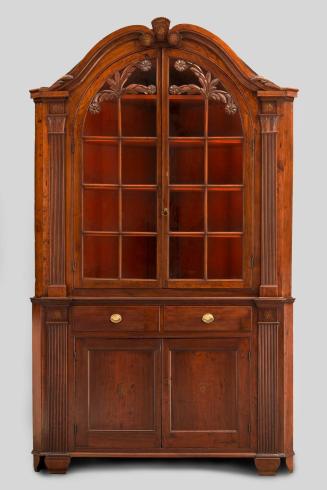

1800-1815

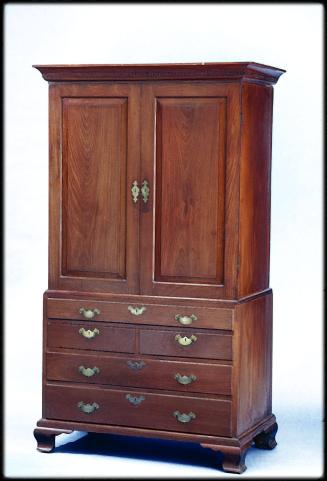

1765-1780

1830-1845

1800-1815

ca. 1740

1760-1780

1815-1830

1760-1780

1780-1820

1790-1810

1760-1790

1840-1850