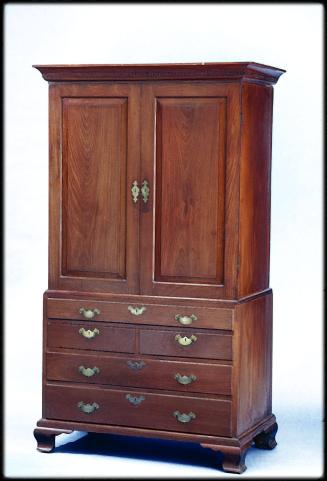

High chest of drawers

Date1700-1730

MediumBlack walnut, yellow pine, white cedar

DimensionsOW: 42 3/4"; OH: 51 1/2"; OD: 24"

Credit LineGift of Mr. & Mrs. Miodrag R. Blagojevich.

Object number1976-434

DescriptionAppearance: High chest of drawers in two parts; upper case has two small drawers over two large graduated drawers surrounded by an applied bead and surmounted by a coved cornice molding; case sides have a recessed flat panel with molded edges on the inner rails and stiles; lower case has a heavy ogee and coved mid molding over one long drawer above a rounded base molding over five baluster, ring, and ball turned legs, three across the front, two at the rear, with flattened ball feet; legs are joined by cyma shaped flat stretchers along the front and sides and a rectangular flat stretcher across the rear; brass ring drawer pulls and engraved escutcheons replaced.Construction: Upper Chest: The top consists of four horizontal 3/8” boards butt joined and resting in rabbets formed by the front and side rails and the mitered top molding which is nailed to the rails and is flush with the upper side of the top. The top boards are through pinned to the front rail, pinned to the stiles and to the top edge of the side rails, where reinforcing modern nails have been added as needed.

The rails of the side panels are tenoned and pinned into the stiles and the resulting frame is dadoed on the inside edge to hold the panel. Modern strips have been nailed to the inside edges of the stiles and bottom rails of the frames to secure the shrinking panels

Drawer blades are tenoned into the side frame stiles and drawer supports are tenoned to the drawer blades and rest in notches in the stiles in the back. Dust boards rest in dados in the drawer blades and drawer supports. Drawer guides are glued to the upper surface of the drawer supports and to the side panels. Replaced supports for the bottom drawer are nailed to the stiles and glued to the bottom. The bottom drawer guides are glued to the lower side rails, with the proper right guide nailed as well.

The vertical full depth drawer divider for the two top drawers is notched to fit around the top front rail and nailed from the back into a dado in the back upper rail. The medial drawer support is nailed from the underside to the divider. Four modern upper drawer guides keep the two upper drawers from tipping. Two are glued to the top on either side of the drawer divider and two are nailed to the side stiles. Square holes have been cut in the dust boards under the two top drawers for access to the wooden spring (Quaker) locks.

The bottom front rail is tenoned into the stiles. The bottom is comprised of three lap joined yellow pine boards nailed into rabbets in the bottom side rails. The foremost board is rabbeted to fit around the front rail and nailed from below to it. Likewise, the rearmost board is rabbeted and nailed from the underside to the back. Both are notched to accommodate the stiles.

The back is comprised of a frame formed by top and bottom rails that are tenoned and pinned into the rear stiles, with two horizontal boards lap joined to the rails and each other and at the ends nailed into rabbets formed by ½”x ½” strips nailed to the stiles.

Drawers are of dovetail construction, with bottoms resting in rabbets in the drawer fronts and nailed to the edges of the sides and backs. Modern drawer runners are glued and nailed with brads to the bottoms underneath the drawer sides; walnut strips have been added on the bottom edge of the front, overlapping the drawer bottom.

Lower Case with Drawer: The three board front to back grained top is face nailed to the back rail, probably nailed to the front and side rails, and notched to fit around all four stiles. The top is further supported by front to back blocks that are nailed to the sides between the legs directly under the top. The sides and back are tenoned and pinned to the stiles. The front rail and drawer blade are tenoned and possibly pinned into the stiles. The stiles are integral with the baluster, ball and ring turned legs which, at the bottom, are turned to form a round tenon that extends through holes in the stretchers and turned ball feet. The shaped stretchers (straight in back) are lap joined and nailed, with holes drilled to allow for the round tenons. Thin square spacers are fitted between the stretcher and the turned area of the legs.

Drawer supports are notched to fit around the stiles and are glued and possibly nailed to the sides from the sides and toe-nailed to the drawer blade. Modern drawer guides are nailed to the drawer supports. Guides to keep the drawer from tipping are nailed to the stiles parallel to the sides and directly below the underside of the top.

A miter joined molding is face nailed to the front and side edges of the top to hold the upper cabinet in place. Beneath that molding and butt joined to it, a mitered cove molding is face nailed to the sides covering the edges of the top and top rail to which it is face nailed. An additional mitered molding is nailed to the front edge of the drawer blade, the stiles and the lower edge of the sides.

Drawers are of dovetail construction with bottoms nailed into rabbets in the drawer fronts and nailed to the edges of the sides and backs. Modern drawer runners are glued and nailed with brads to the bottoms underneath the drawer sides

Woods: On both upper case and lower frame the primary wood is black walnut with yellow pine as secondary; drawer bottoms and dustboards are of white cedar.

1735-1750

1800-1815

ca. 1760

1790-1810

1815-1830

1710-1740

1821

1710-1725

1810-1820

Ca. 1810

ca. 1798

1760-1780